Stainless Steel Shots

Precision-Cut Wire Shot - Engineered for Consistent, High-Performance Surface Treatment

Stainless Steel Shots as Cut

Product Overview

- Manufacturing Process: Produced by precisely cutting high-grade stainless steel wires into cylindrical particles.

- Edge Retention: Retains sharp, cut edges during the cutting process.

- Clean Blasting: Provides exceptional cleaning performance by delivering a dust-free, bright, and smooth surface due to the absence of scales or oxides.

- Applications: Ideal for blasting in industries such as castings, aluminum die castings, and brass components where carbon contamination is harmful.

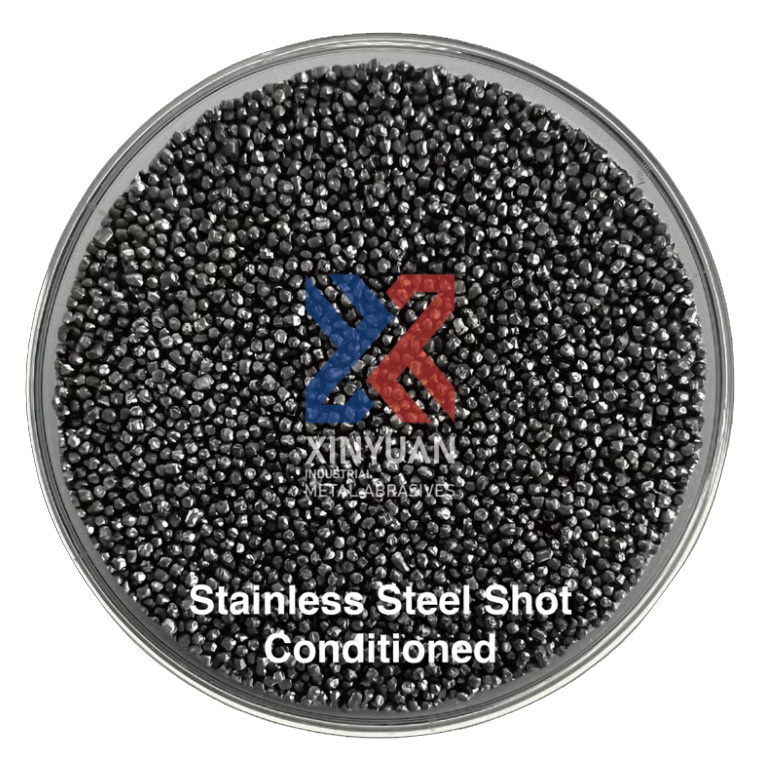

Stainless Steel Shots Conditioned

Product Overview

- Additional Processing: Undergoes an advanced conditioning process after cutting to round off sharp edges.

- Spherical Form: Produces nearly perfect spherical particles available in multiple grades (G1 - normal, G2 - double, G3 - special/most rounded).

- Enhanced Performance: Offers superior surface finish, optimal shot peening performance, and minimal contamination.

- Applications: Widely used in shot peening for industries such as automotive, aerospace, medical, and shipping, where precise surface treatment is crucial.

Shape:

- Available in "as cut" and cylindrical shapes

- G1/G2/G3 Conditioned

Material Options:

- Stainless Steel SUS410 (SS410)

- Stainless Steel SUS430 (SS430)

- Stainless Steel SUS201 (SS201)

- Stainless Steel SUS202 (SS202)

- Stainless Steel SUS304 (SS304)

- Stainless Steel SUS316 (SS316)

Hardness:

- Ranges from HV400-500 / HV500-600, HV600-700

- Equivalent to HRC 45~55

Density:

- 7.46 - 7.93 g/cm³

Shot Sizes:

Ranges from HV400-500 / HV500-600, HV600-700 Equivalent to HRC 45~55

Density:

- Available in a wide range of sizes:

- Fine sizes: 0.2mm, 0.3mm, 0.4mm, 0.5mm, 0.6mm

- Coarse sizes: 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm

Explore our products

Provide a short description of categories listed below.